Considering the large capital investment required for the construction of a glass melting furnace, reaching and possibly surpassing the planned service lifetime is a fundamental element in determining its profitability.

Considering the large capital investment required for the construction of a glass melting furnace, reaching and possibly surpassing the planned service lifetime is a fundamental element in determining its profitability.

Innovative engineering solutions and continuous technological development of refractory materials have helped in the substantial improvement of the average duration of furnace production campaigns, but monitoring the ageing of the interior of the melting tank and the periodic inspection of the status of refractory linings remain always fundamental practices, thanks to which corrosion and wear anomalies can be highlited before causing severe damage, and eventual maintenance operations (hot repair, tackling, etc..) to allow the safe continuation of production can be timely planned.

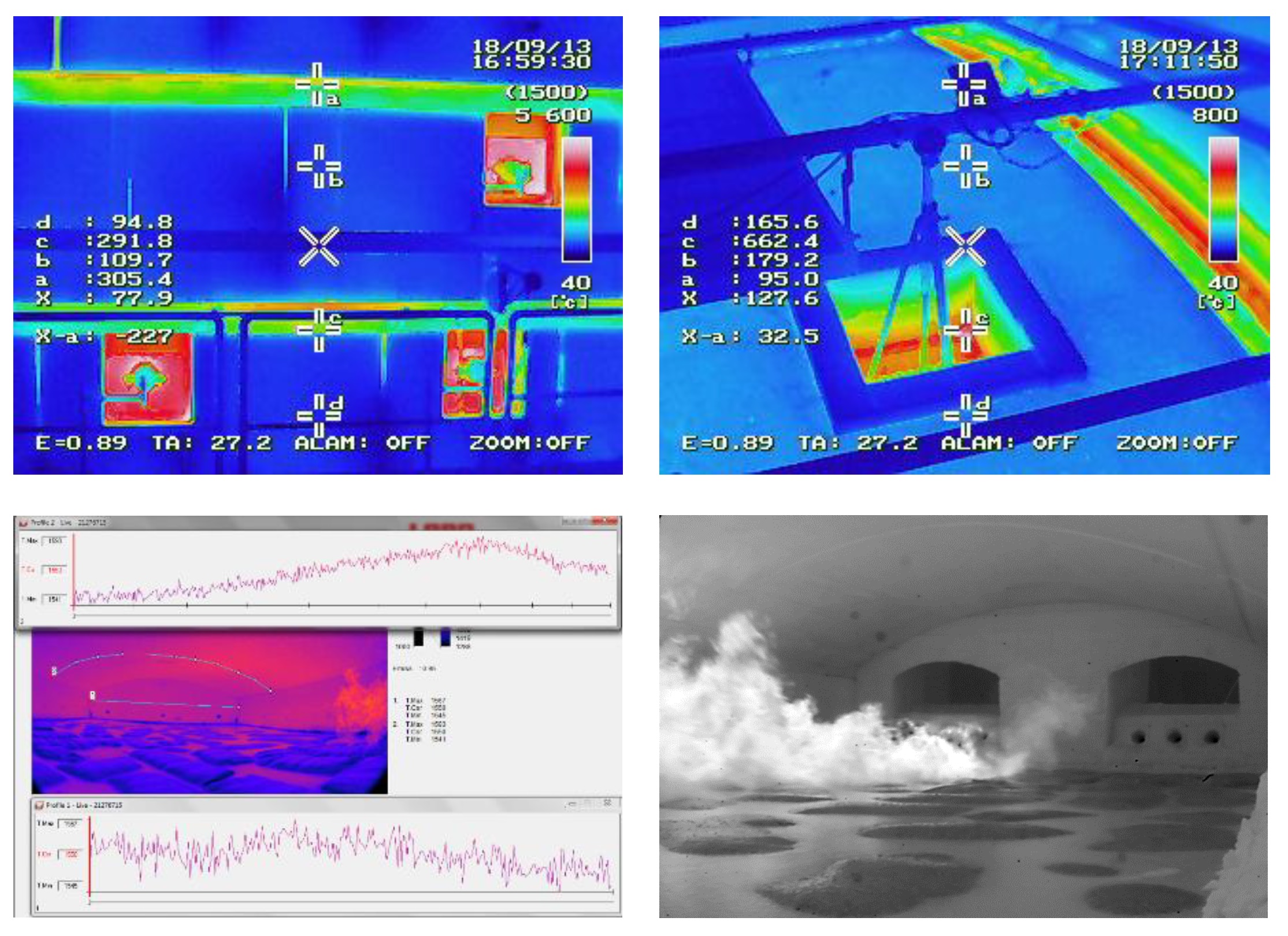

To this end, Stazione Sperimentale del Vetro offers a dual service: on one hand, a 360° internal endoscopic inspection of the status of furnace superstructure and of the regeneration chambers, including a high-definition photographic report indicating any anomalies in the refractories (cracks, cold spots, meltdowns, subsidence, etc.); on the other hand, a thermographic mapping of the external surfaces of the furnace, which allows the identification of any hot spots or other external symptoms of possible localised damage to the internal lining.